ʻAʻole i hana wale ʻia kahi huahana maikaʻi, akā koi pū kekahi i nā ʻano lapaʻau like ʻole e hoʻokō ai i ka pale ʻana i ka corrosion, pale ʻana i ka pale, aesthetics, a hoʻonui i ke ola lawelawe.Loaʻa iā RCT MFG nā makahiki he nui o ka ʻike ma ka hana CNC a me ka hoʻoheheʻe ʻana i ka injection, hāʻawi pū kekahi i kahi ʻano o nā lawelawe mai ka hana ʻana i ka mālama ʻana i ka ʻili a hiki i ka hui.No laila, ma waho aʻe o ka ʻenehana hana, loaʻa iā ia ka ʻike waiwai i ka mālama ʻana i ka ʻili.ʻO nā kaʻina hana lapaʻau i loaʻa i kēia manawa: pena, pena Baking, uhi pauka, sandblasting, pana pana, anodizing, anodizing film mānoanoa, micro-arc anodizing, electroplating, electrophoresis, laser engraving, silk screen printing, brushed metal, mirror polishing, dyeing, ʻeleʻele, CD pattern, etching, high gloss, etch pattern , Epoxy, etc., kōkua e hana i kāu huahana i kahi kiʻekiʻe.

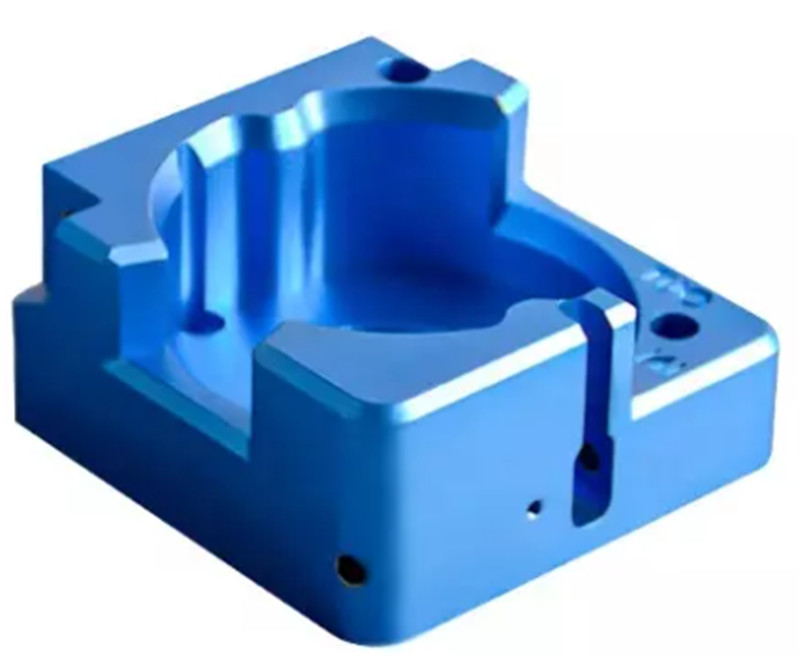

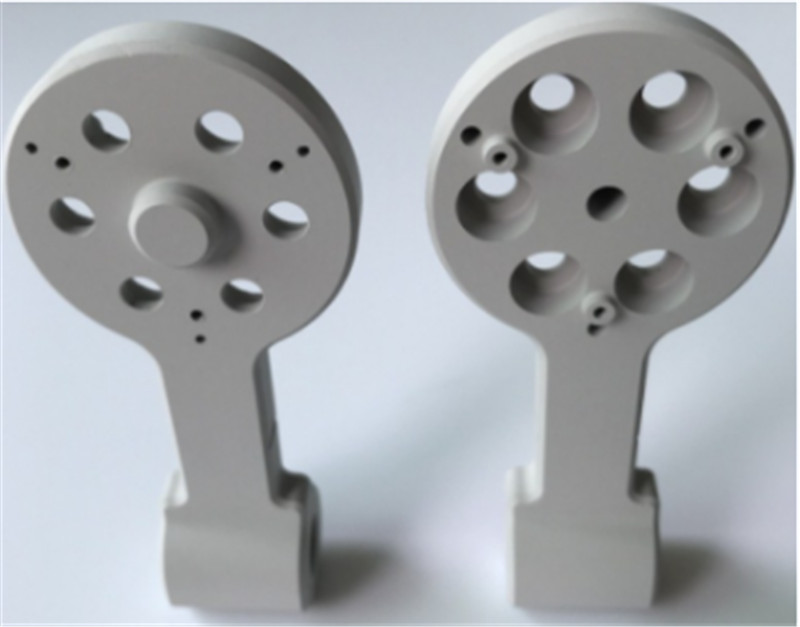

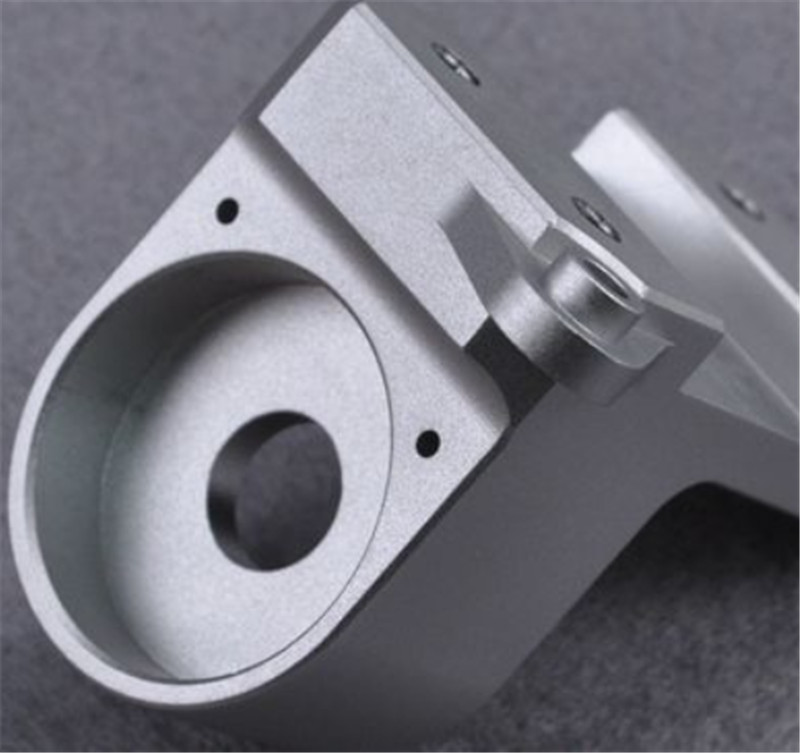

Anodizing

He kaʻina hana electrolytic oxidation, e hoʻohuli ana i ka ʻili o ka mea i kahi kiʻi pale, e paʻakikī i ka oxidize a me ka corrode, e hoʻolōʻihi i ke ola a loaʻa i ke ʻano o nā kala like ʻole.Ua maheleia na anodizing ma'amau i: anodizing ma'amau , brushed metala anodizing, hard anodizing, manoanoa film anodizing, micro-arc oxidation, etc. O na mea i hiki ke oxidized he: aluminika aluminika, magnesium alloy, titanium alloy, etc.

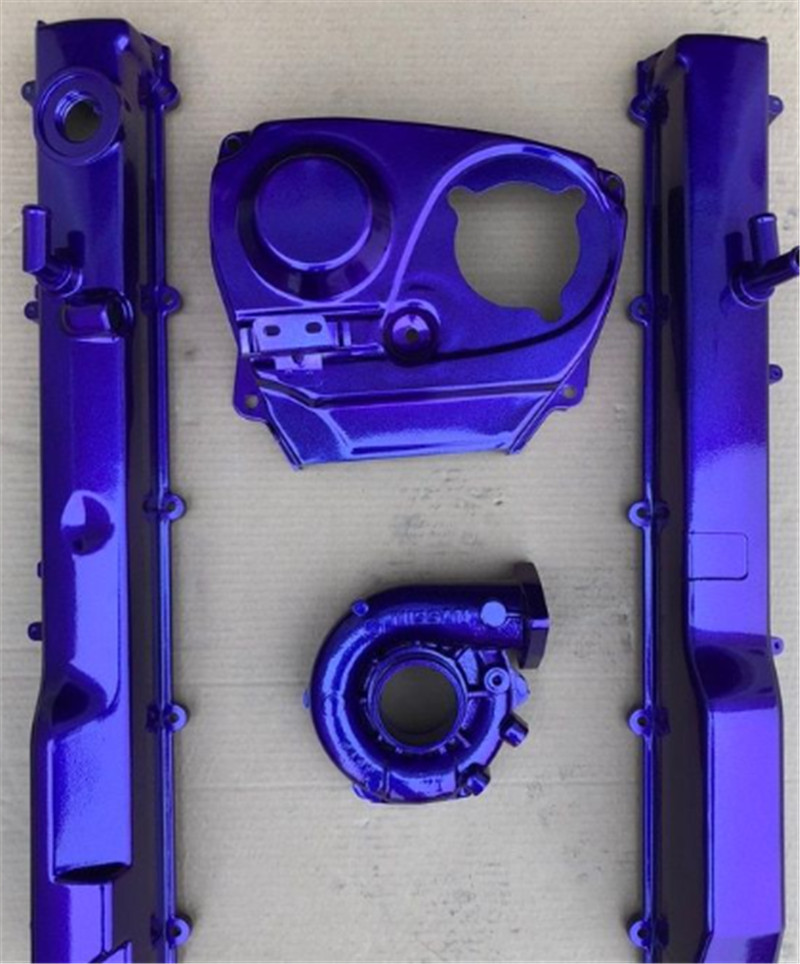

Electroplating

ʻO ke kaʻina hana maʻamau o ka electroplating e hoʻokomo i ka ʻāpana i loko o ka hopena o ka paʻakai metala e like me ka cathode, a me ka pā metala e like me ka anode, a hele i kēia manawa e waiho i ka uhi i makemake ʻia ma ka ʻāpana.ʻO ka hopena electroplating kūpono e hoʻonui i kāu huahana i ke ʻano kiʻekiʻe a me ia.I kahi mākeke ʻoi aku ka maikaʻi, ʻo ka electroplating maʻamau e pili ana i ka pā keleawe, ka nickel plating, ka plating kālā, ka pā gula, ka chrome plating, galvanizing, tin plating, vacuum plating, etc.

ʻO ka uhi uila

Me ka hoʻomau mau ʻana o ka noi ʻoihana, hiki i ka ʻenehana coating Electrophoretic ke hana i nā kala like ʻole, mālama i ka luster metallic a hoʻonui i ka pale ʻana o ka ʻili, he liʻiliʻi ka hopena i ka pololei o ka huahana.ʻO ka mānoanoa ma kahi o 10-25um, a hiki ke hoʻopili ʻia nā mea mānoanoa

Ka hoʻopaʻapaʻa

ʻO ka passivation, ʻike ʻia hoʻi ʻo ka chromate treatment, kahi kaʻina pickling e hoʻoneʻe i ka momona o ka ʻili, ka ʻōpala, a me nā oxides ma ka hoʻomaʻemaʻe ʻana a i ʻole ka hoʻomaʻemaʻe ultrasonic.Ma o ka hopena kemika o ka hopena passivation, hiki iā ia ke pale i ka corrosion a hoʻolōʻihi i ka ʻōpala.E hoʻololi ke kala o ke kiʻi passivation me nā mea like ʻole.ʻAʻole e hoʻonui ka passivation i ka mānoanoa o ka huahana, a ʻaʻohe pono e hopohopo e pili ana i ka pili ʻana i ka pololei o ka huahana.

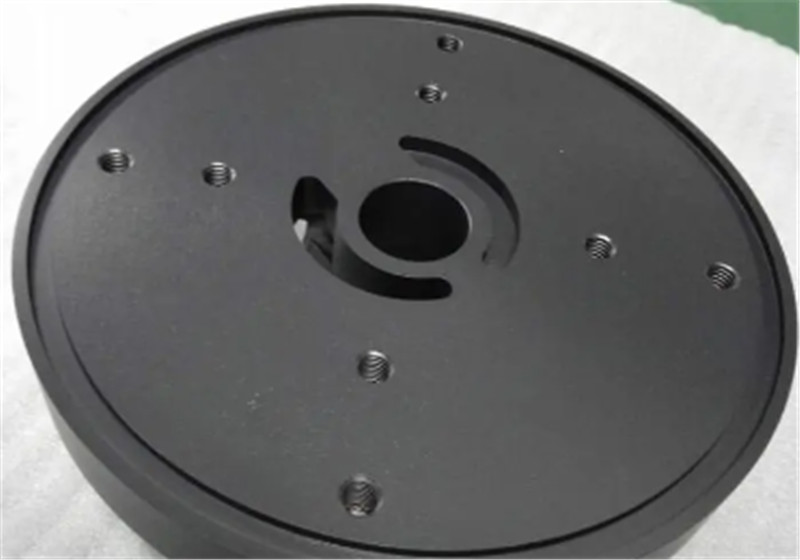

ʻeleʻele

Kapa ʻia ʻo ka ʻeleʻele he bluing.ʻO ke kumu o ka hoʻoinu ʻana i ka huahana i loko o kahi hopena kemika oxidizing ikaika e hana i kahi kiʻiʻoniʻoni oxide ma ka ʻili metala e hoʻokaʻawale i ka ea a hoʻokō i ke kumu o ka pale ʻana i ka ʻōpala.Pili kēia kaʻina hana i nā mea kila.

QPQ (Quench-Polish-Quench)

E pili ana i ka waiho ʻana i nā ʻāpana metala ferrous i ʻelua ʻano ʻauʻau paʻakai me nā waiwai like ʻole, a me ka hoʻokomo ʻana i nā mea like ʻole i loko o ka ʻili metala e hana i kahi papa infiltration composite, i hiki ai ke hoʻokō i ke kumu o ka hoʻololi ʻana i ka ʻili o nā ʻāpana.Loaʻa iā ia ke kūpaʻa ʻaʻahu maikaʻi, ke kūpaʻa luhi, ke kūpaʻa corrosion a me ka deformation liʻiliʻi.Pili kēia kaʻina hana i nā mea kila a pau.

(E hoʻomanaʻo: ʻAʻole hiki ke ʻeleʻele nā huahana kila kila, a hiki ke ʻeleʻele wale ka ʻili e QPQ)

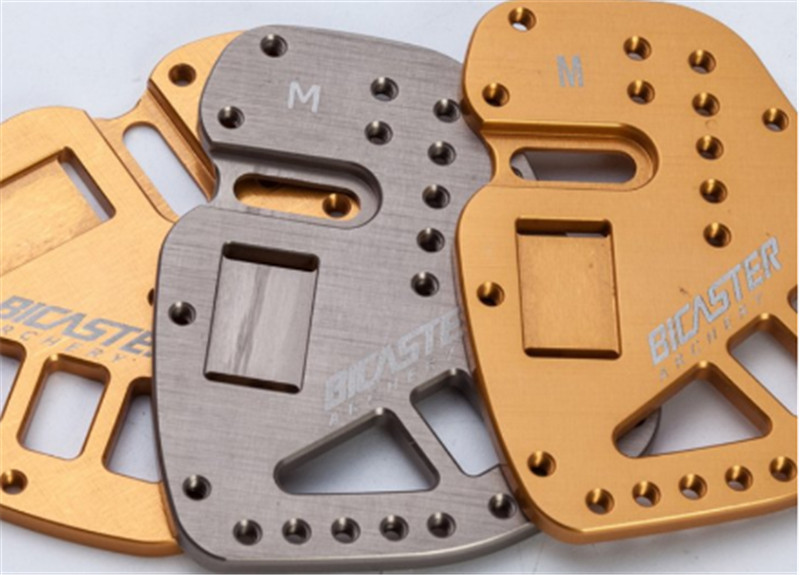

Ke kalai laser

ʻO ke kahakaha ʻana i ka laser, i kapa ʻia hoʻi ka mākaʻikaʻi laser, kahi kaʻina hana lapaʻau ma ka hoʻohana ʻana i nā loina optical e hana i LOGO a i ʻole nā hiʻohiʻona ma nā huahana.Paʻa mau ka hopena engraving laser, kiʻekiʻe ka maikaʻi o ka ʻili, a kūpono ia i nā huahana i hana ʻia i nā mea metala a me nā mea plastic.

Pai kilika

ʻO ka paʻi kiʻi silika, ʻo ia ka hoʻololi ʻana o ka ʻīnika i ke kumu i ka huahana ma o ka pale.Hiki ke hoʻopilikinoʻia ke kala o ka'īnika e like me ka makemake o nā mea kūʻai.Ua hana ʻo RCT MFG i 6 mau kala ma ka huahana like, me ka ʻeleʻele, ʻulaʻula, uliuli, melemele a keʻokeʻo.,ʻōmaʻomaʻo.Inā makemake ʻoe i ka hopena o ka paʻi kilika e ʻoi aku ka lōʻihi, hiki iā ʻoe ke hoʻohui i kahi papa o UV ma hope o ka paʻi kilika e hoʻolōʻihi i kona ola.He kūpono ka paʻi kiʻi kilika no nā mea metala a me ka plastic, a hiki ke hoʻohui pū ʻia me ka mālama ʻana i ka ʻili e like me ka oxidation, ka pena, ka pauka lepo, electroplating, a me electrophoresis.

ʻO ka hoʻopololei

ʻO ka polishing ka mea e nani ai ka huahana, translucent a pale i ka ʻili.He koho maikaʻi ka poli a me ka ʻike.Hoʻokaʻawale ʻia ka polishing o nā huahana lako i ka polishing manual, mechanical polishing, a me ka electrolytic polishing.Hiki ke hoʻohana ʻia ka electrolytic polishing e hoʻololi i ka polishing mechanical kaumaha, ʻoi aku hoʻi no nā ʻāpana me nā ʻano paʻakikī a me nā ʻāpana paʻakikī ke hana ʻia e ka polishing manual a me nā hana mechanical.Hoʻohana pinepine ʻia ka polishing electrolytic no ke kila, aluminika, keleawe a me nā ʻāpana ʻē aʻe.

Metala palaki

ʻO ka metala ʻo Brushed kahi ʻano hana lapaʻau ʻili e hana i nā laina ma ka ʻili o ka mea hana ma o ke kāʻei abrasive paʻa paʻa a me ka pulupulu ʻaʻole i ulana ʻia e hoʻokō i kahi hopena hoʻonaninani.Hiki ke hoʻohālikelike ʻia ka hoʻomaʻamaʻa ʻana i ka ʻili o ka ʻili i ke ʻano o nā mea metala, a ke lilo nei ia i mea kaulana loa i ke ola hou.Hoʻohana nui ʻia ia i nā kelepona paʻalima, nā kamepiula, nā mea nānā, nā lako, nā mea uila a me nā pūpū ʻē aʻe.

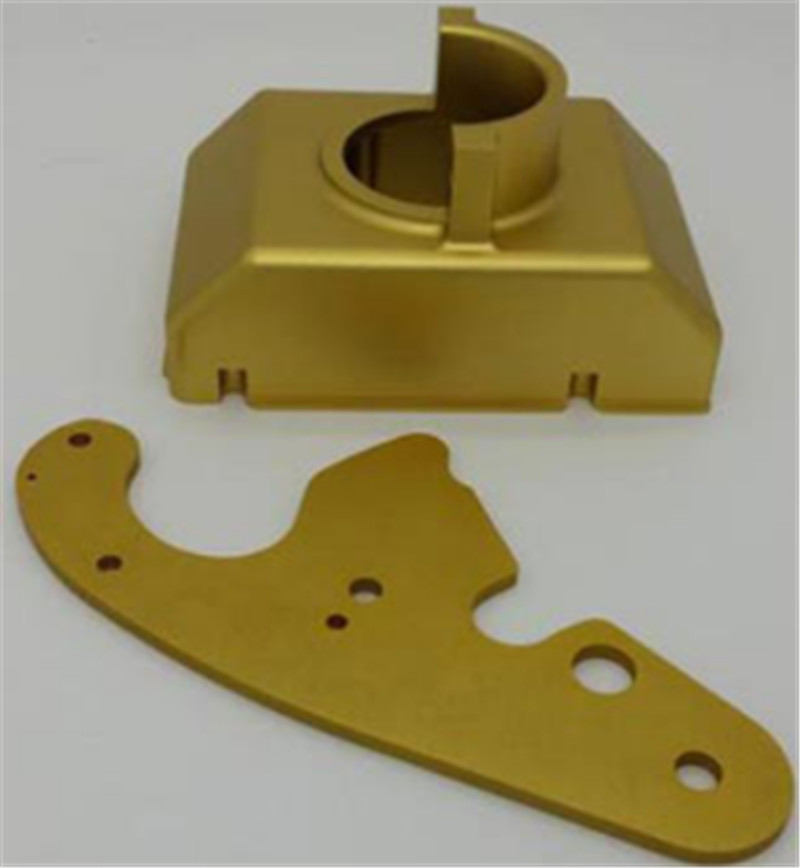

Paʻi pena a me ka pauka

ʻO ka pulupulu pena a me ka pulupulu pauda ʻelua mau lāʻau lapaʻau maʻamau i loko o nā ʻāpana hāmeʻa, a ʻo ia nā lāʻau lapaʻau maʻamau i hoʻohana ʻia no nā ʻāpana kikoʻī a me ka hoʻoponopono ʻana i nā ʻāpana liʻiliʻi.Hiki iā lākou ke pale i ka ʻili mai ka corrosion, rust, a hiki ke hoʻokō i kahi hopena aesthetic.Hiki ke hoʻopilikino ʻia ka pauka a me ka pena kiʻi me nā ʻano ʻano like ʻole (nā laina maikaʻi, nā laina ʻili, nā laina ʻili, a me nā mea ʻē aʻe), nā kala like ʻole, a me nā pae ʻoniʻoni like ʻole (matte, flat, high-gloss).

Sandblasting

ʻO Sandblasting kekahi o nā lāʻau lapaʻau maʻamau no nā huahana lako.Hiki iā ia ke hoʻomaikaʻi i ka maʻemaʻe a me ka roughness, a hoʻonui i ka adhesion a me ka lōʻihi ma waena o ka huahana a me ka uhi.No laila, he nui nā lāʻau lapaʻau e koho i ka sandblasting e like me kā lākou hana mua.E like me: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + pena, sandblasting + passivation, etc.

Hoʻopā ʻia ʻo Teflon

Kapa ʻia hoʻi ʻo Teflon spraying, he lāʻau lapaʻau kūʻokoʻa loa ia.Loaʻa iā ia nā hiʻohiʻona kiʻekiʻe o ka anti viscosity, non viscosity, kiʻekiʻe wela ke kūpaʻa, haʻahaʻa haʻahaʻa, kiʻekiʻe paʻakikī, ʻaʻole pulu, a me ke kūpaʻa kiʻekiʻe.No laila, hoʻohana nui ʻia i ka ʻoihana meaʻai, nā papa ʻaina, nā kīhini, nā ʻoihana pepa, nā mea lapaʻau, nā huahana uila a me nā huahana kaʻa, nā mea kemika, a me nā mea ʻē aʻe, a hiki ke pale aku i nā mea mai ka corrosion kemika e hoʻonui i ke ola lawelawe o nā huahana.

Kaʻi ʻana

ʻO ka etching ke ʻano o ka wehe ʻana i nā mea me ka hoʻohana ʻana i nā hopena kemika a i ʻole ka hopena kino.ʻO ka maʻamau e pili ana i ka etching, i ʻike ʻia hoʻi he photochemical etching, e pili ana i ka wehe ʻana i ke kiʻi pale o ka wahi e hoʻopaʻa ʻia ma hope o ka hana ʻana a me ka hoʻomohala ʻana o ka pā, a me ka hoʻopili ʻana i ka hopena kemika i ka wā etching e hoʻokō i ka hopena o ka dissolution a me ka corrosion, hana i ka hopena o concave-convex or hollow molding.

IMD

ʻO ka In Mold Decoration (IMD) kahi ala kūpono no ka hoʻonani ʻana i nā ʻāpana plastik.Aia ia i ʻehā mau ʻanuʻu: Paʻi, Hoʻokumu, Trimming a Injection Molding.A He ʻenehana hoʻonaninani honua kaulana ia.ʻO ke kiʻiʻoniʻoni paʻakikī a ʻike maopopo ka ʻili, ka papa waena o ka paʻi paʻi ʻana, ka papa hoʻoheheʻe hope, a ʻo ka waena o ka inika hiki ke hana i ka huahana kūʻē i ka friction., pale i ka ʻili mai ka ʻoki ʻia ʻana, a hiki ke mālama i ke kala a ʻaʻole maʻalahi e mae no ka manawa lōʻihi.

Paʻi Pad

ʻO ka paʻi pad, i kapa ʻia hoʻi ka tampography a i ʻole ka paʻi tampo, he kaʻina hana paʻi indirect offset (gravure) kahi e kiʻi ai kahi pahu silika i kahi kiʻi 2-D mai kahi pā paʻi laser i kahakaha ʻia (i kapa ʻia ʻo cliché) a hoʻololi iā ia i kahi 3- D mea.Mahalo i ka paʻi pad, hiki i kēia manawa ke paʻi i nā ʻano huahana like ʻole e like me ka curved (convex), hollow (concave), cylindrical, spherical, compound angles, textures, etc.

Paʻi lawe wai

ʻO ka paʻi hoʻoili wai he ʻano paʻi e hoʻohana ana i ke kaomi wai e hydrolyze i ka pepa hoʻololi / kiʻiʻoniʻoni me nā ʻano kala.ʻO ke kaʻina hana ʻenehana ka hana ʻana i ka pepa paʻi hoʻoili wai, hoʻoluhi i ka pepa pua, hoʻololi kumu, hoʻomaloʻo, a me ka huahana i hoʻopau ʻia.

Hoʻopili hoʻoheheʻe

ʻO ka uhi hoʻoheheʻe ʻana he ʻano pena i hiki ke hoʻohana ʻia no ka pulupulu ʻana.Hiki iā ia ke alakaʻi i ka uila ma hope o ka maloʻo ʻana e hana i kahi kiʻi pena, i mea e pale ai i ka hoʻopili electromagnetic.I kēia manawa, hoʻohana ʻia ia i nā ʻoihana koa a me nā ʻoihana kīwila e like me ka uila, nā mea uila, ka mokulele, ka ʻoihana kemika, paʻi, etc.

Ka manawa hoʻouna: Apr-11-2023